Nochu

Thành viên rất năng động

INTRODUCTION

1.1 Introduction

The Vung Ang II thermal power plant is part of the Vung Ang thermal power center and is the second complex of the coal-fired electricity generating plant located in the Vung Ang industrial zone, Ky Loi commune, Ky Anh district, Ha Tinh province in Vietnam. Vung Ang II will be constructed adjacent to Vung Ang I which is already in operation. It consists of two turbines with a total capacity of 1,200 MW. Both will be fueled by imported anthracite, hard coal.

1.2 Abbreviation and definition

The Owner Vung Ang II Thermal Power LLC

The Contractor DHI-SCT Joint Venture

HSE Health, Safety and Environment

MS Method Statement

RA Risk Assessment

PPE Personal Protective Equipment

QA/QC Quality Assurance/Quality Control

1.3 Scope of work

To install the CW underground pipeline of Vung Ang 2 Thermal Power Plant at crossing area with Vung Ang 1 belt conveyor by pipe jacking pressing method.

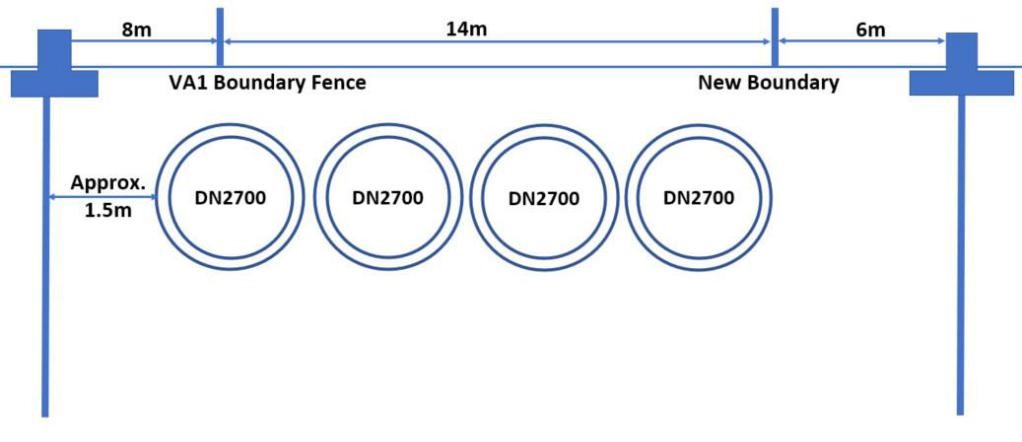

1.3.1 Constructing of 04 CW pipelines with Diameter 2700mm

Number of CW pipelines can be changed with 2 pipelines (DN 3700) at the detail engineering stage

2 OVERVIEW

CW pipe DN2700 to install underground by Pipe jacking method.

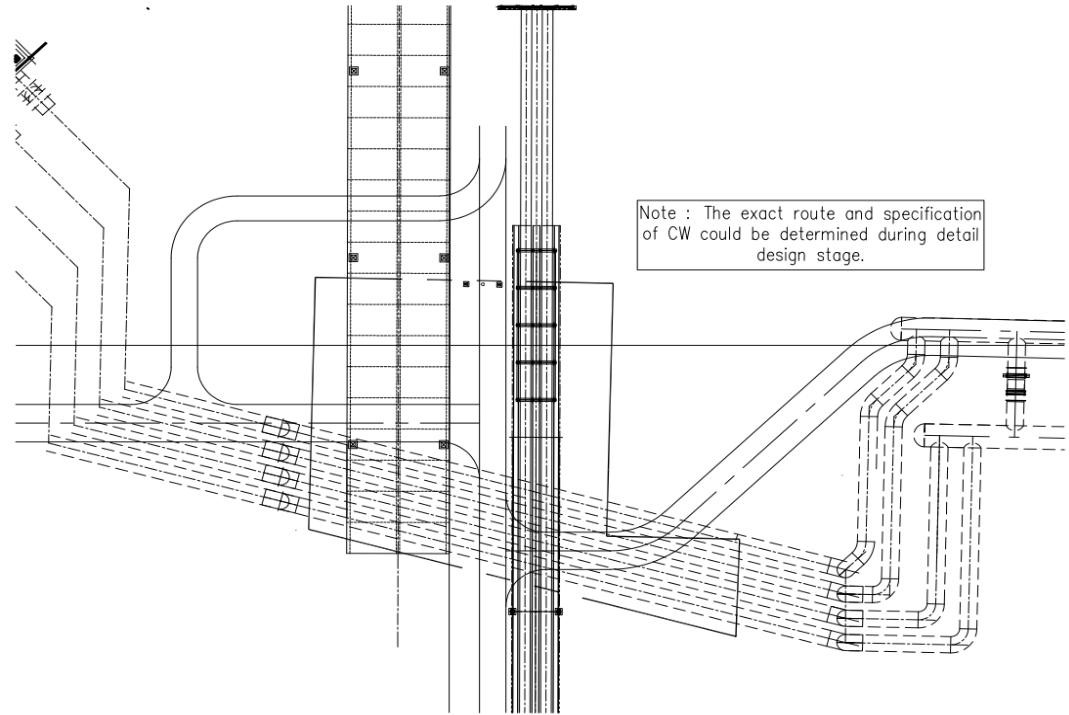

Plan View of Construction Location

Table 1.1 Contents of work

3 METHOD STATEMENT

3.1 Shaft construction

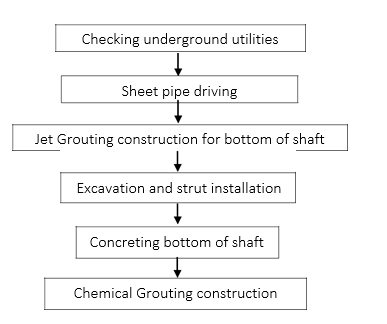

3.1.1 Construction sequence

3.1.2 Sheet pile construction

a. Preparation work

Approved all documents

Mobilization equipment and materials.

b. Survey work

Use total station machine to setting up.

Marking point by paint on the site.

Checking underground utilities.

c. Sheet pile driving

Checking weather before construction

Welding sheet pile with length of design.

Use crane to lifting sheet pile for driving.

Sheet pile driving with checking alignment by water ruler.

d. Cleaning after construction

Remove all materials and rubbish,

Keep clean of site.

e. Construction sequence

Xem tiếp METHOD STATEMENT FOR PIPE JACKING WORK >>

1.1 Introduction

The Vung Ang II thermal power plant is part of the Vung Ang thermal power center and is the second complex of the coal-fired electricity generating plant located in the Vung Ang industrial zone, Ky Loi commune, Ky Anh district, Ha Tinh province in Vietnam. Vung Ang II will be constructed adjacent to Vung Ang I which is already in operation. It consists of two turbines with a total capacity of 1,200 MW. Both will be fueled by imported anthracite, hard coal.

1.2 Abbreviation and definition

The Owner Vung Ang II Thermal Power LLC

The Contractor DHI-SCT Joint Venture

HSE Health, Safety and Environment

MS Method Statement

RA Risk Assessment

PPE Personal Protective Equipment

QA/QC Quality Assurance/Quality Control

1.3 Scope of work

To install the CW underground pipeline of Vung Ang 2 Thermal Power Plant at crossing area with Vung Ang 1 belt conveyor by pipe jacking pressing method.

1.3.1 Constructing of 04 CW pipelines with Diameter 2700mm

Number of CW pipelines can be changed with 2 pipelines (DN 3700) at the detail engineering stage

2 OVERVIEW

CW pipe DN2700 to install underground by Pipe jacking method.

Plan View of Construction Location

Table 1.1 Contents of work

No | Items | Method statement | Quantities | Note |

A | Shaft construction | | ||

1 | Driving and extract steel sheet pipe Larsen IV | Use Silent Piler(100-150T) | | |

2 | Soil improvement for bottom of shaft | Jet Grouting D1800 | 2shaft | |

3 | Soil improvement for entrance of launching and arriving shaft | Jet Grouting D1200 | | |

4 | Strut installation | Lifting and installing | | |

5 | Soil Excavation | Use excavator | | |

B | Pipe jacking construction | | ||

1 | Supply DN2700 pipe | | ||

2 | Installation CW pipe DN2700 | Pipe Jacking | 40m |

3 METHOD STATEMENT

3.1 Shaft construction

3.1.1 Construction sequence

3.1.2 Sheet pile construction

a. Preparation work

Approved all documents

Mobilization equipment and materials.

b. Survey work

Use total station machine to setting up.

Marking point by paint on the site.

Checking underground utilities.

c. Sheet pile driving

Checking weather before construction

Welding sheet pile with length of design.

Use crane to lifting sheet pile for driving.

Sheet pile driving with checking alignment by water ruler.

d. Cleaning after construction

Remove all materials and rubbish,

Keep clean of site.

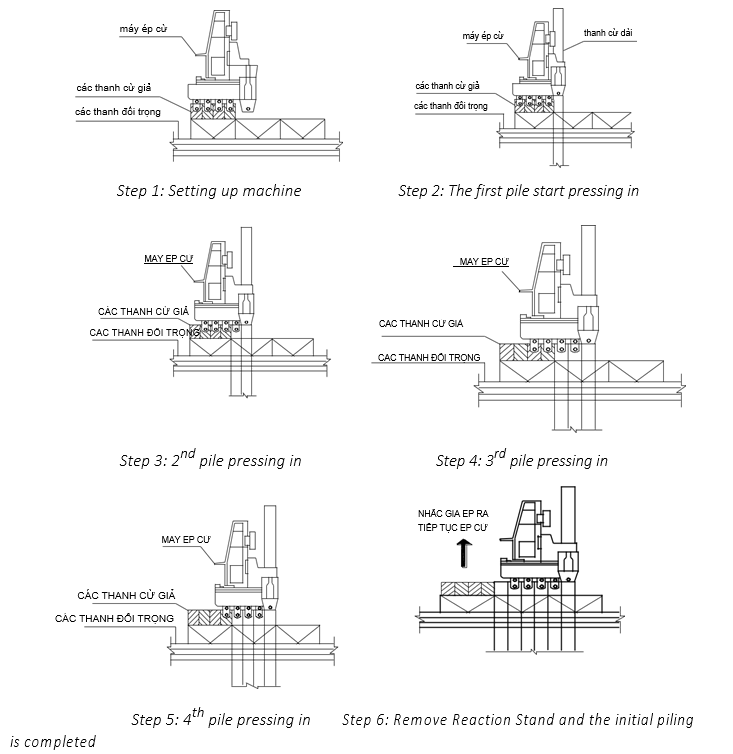

e. Construction sequence

Xem tiếp METHOD STATEMENT FOR PIPE JACKING WORK >>